Slitting

High-speed precision slitting of steel coils to custom widths, ensuring

High-speed precision slitting of steel coils to custom widths, ensuring

We provide precision coil slitting to custom strip widths, offering efficiency and material optimization for fabrication, automotive, packaging, and industrial sectors.

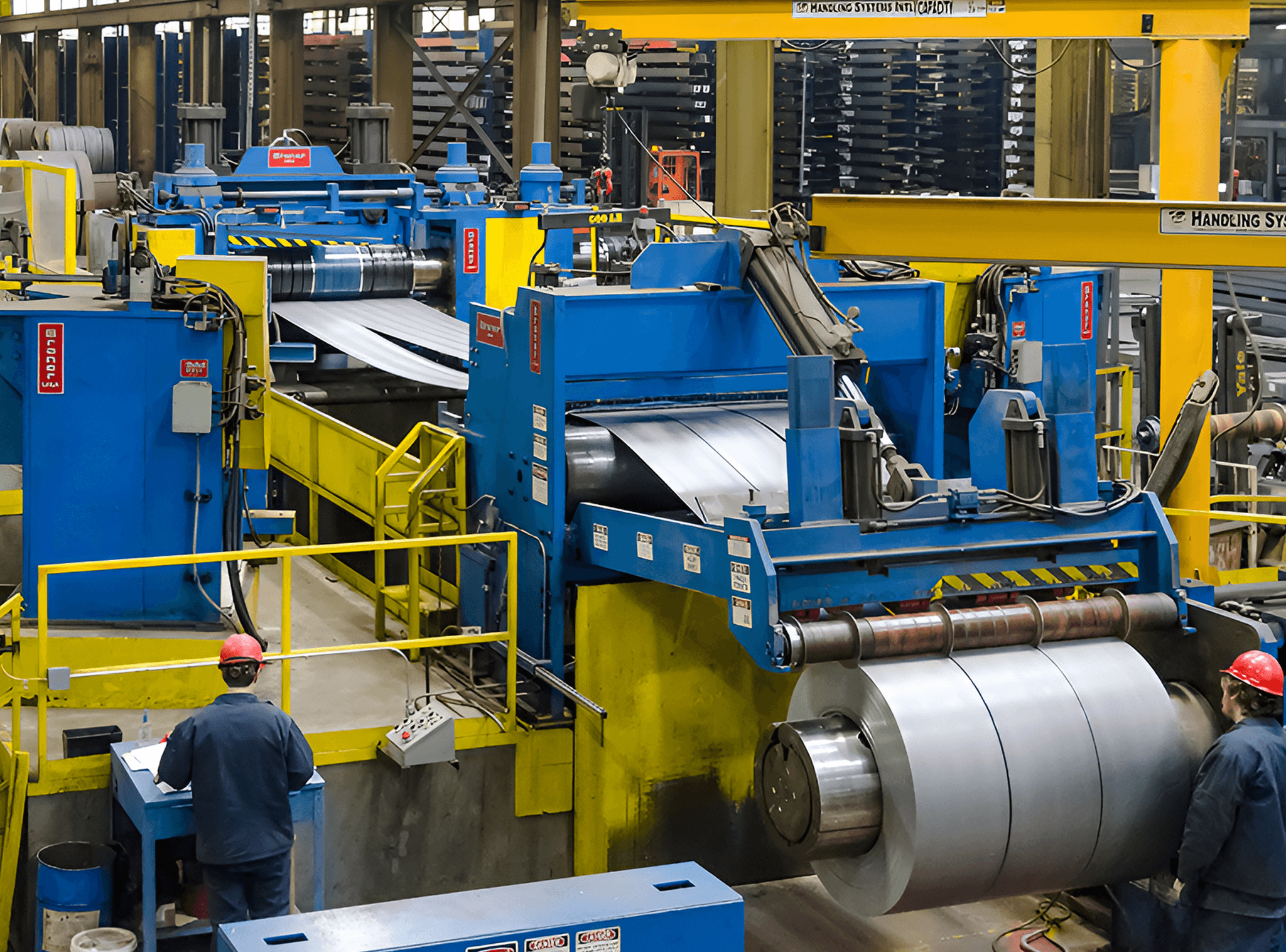

Our steel slitting service transforms wide metal coils into narrow, high-quality strips with razor-sharp edges, consistent width, and clean finishes. With this process, customers experience improved line efficiency, reduced material handling, and less waste—translating to overall cost savings and operational precision.

Used widely in automotive, construction, packaging, HVAC, and appliance manufacturing, slitting ensures metal coils are ready for stamping, welding, or assembly.It's the most effective way to tailor coil widths for exact production needs while maintaining structural integrity and surface quality.It's the most effective way to tailor coil widths for exact production needs while maintaining structural integrity and surface quality.

Our slitting process begins by unwinding steel coils and feeding them through high-precision rotary knives that cut the material into narrower strips. These strips are then rewound onto individual recoilers, each tailored to your core and diameter requirements.

We ensure minimal burrs, precise edge condition, and uniform tension control using advanced blade alignment and digital automation systems. Our expert operators regularly inspect the setup, ensuring every strip meets exact thickness and width specifications—ready for seamless downstream processing.

Slash waste and boost productivity with Ackroll’s expertise in coil slitting. Our precision tools and real-time quality checks ensure you receive clean, dimensionally accurate slit coils—ready for roll-forming, stamping, or resale. Improve output efficiency with tighter coil tolerances tailored to your manufacturing process.

By choosing Ackroll’s Slitting Service, you benefit from versatile thickness handling (0.30 mm–3 mm) and width ranges (30 mm–1500 mm), compatible with CRCA, HRPO, and galvanized steel. We offer edge conditioning, rewinding, and real-time inspection to ensure consistent output. Our advanced machines minimize burrs and maximize yield while handling high-speed slitting operations. With tight tolerance control and skilled manpower, your slit coils are fully optimized for roll forming, panel cutting, stamping, ductwork fabrication, and other precision applications.

Handles 0.30–3 mm coils with consistent performance across grades.

Produces slit widths from 30 mm to 1500 mm with accuracy.

Works with CRCA, HRPO, galvanized, and coated steel coils effectively.

Produces smooth, burr-free edges for safe, consistent handling.

Offers customized coil rewinding on specified cores and inner diameters.

Integrates digital measuring systems for 100%-dimension accuracy and edge control.

Looking for a trusted steel partner? Reach out to Ackroll for product queries, services, and latest steel market insights. Our team is ready to support your needs with reliable solutions.

Contact Us Now